The Beardsley MakerSpace is a welcome resource for students, faculty and staff who are eager to create and realize their ideas physically. MakerSpace Manager Russell Prigodich and the Academic Techology team are ready to help you realize your ideas in real objects.

With the goal of helping others better understand how the MakerSpace can serve your academic goals we were recently able to interview frequent MakerSpace user, and student technologist, Tracy Tang, after hearing about how her successful applications into several Graduate Architecture and Design programs, were made possible through the use of the MakerSpace.

Q: Hi Tracy, What’s your major?

Q: Hi Tracy, What’s your major?

A: Art Major, Engineering Minor

Q: Has access to the Maker Space helped you here at Swarthmore?

A: Yes, definitely. The technology was not easy, but it helped with my specific architectural projects. How space affects people is my goal, and the physical constructs enabled by 3D printing definitely help with that.

Q: What tools did you use in the Maker Space and how did they help you?

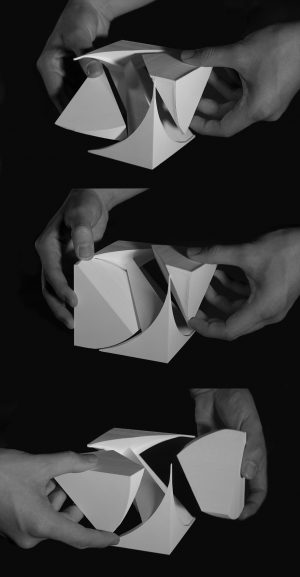

A: The 3D printer visually verified and supplemented my ideas instead of card based or acrylic layered approaches that are traditional in this area. My goal is to emphasize the spatial relationships of the project, which I could achieve using 3D printing. I did not want people to get distracted by the quality of materials or colors.

Q: Tell me more about the process?

A: The digital approach was challenging, but necessary for my projects. The cubes in my design simply could not have been produced manually. Realizing my ideas through digital software and 3D printing was the only way to make it visually accessible to myself and to others.

Q: What challenges did you face?

A: I did encounter some problems during printing, but things generally printed well in small scales.

Q: What did that teach you?

A: The challenges I faced helped me to learn about the flaws of the 3D printing process, and more specifically, taught me how to adjust my designs in the future to accommodate real-world issues such as gravity and some of the structural issues with my designs. For example, with one of my designs, I tried rotating it to different positions relative to the print-head and print surface, but quickly realized that the symmetry of the design was fundamentally problematic for that model.

Q: How did the experience using the Maker Space impact your application to Grad School?

A: 3D printing is very efficient compared to making models by hand. I could work on the digital model anytime and anywhere. If I had to make my works out of wood, I would face a lot more limitations such as shop time, hours and safety.

The production process took a lot of trials. I recognize that lots of higher institutions are interested in this technology and I think it helped with my applications to those institutions. The admissions can see photos of my models that were 3D printed. Without the technology offered by the Maker Space, I don’t think I’d be able to apply this year, or even finish my applications to be honest.

Q: Any more thoughts?

A: At the Maker Space in Academic Technology in ITS in Beardsley, I could get help on a daily basis, especially during breaks when staff are still here. Problems get fixed really quickly too. For example, when I ran out of a particular white color of material, the staff quickly ordered more and had my projects going again as soon as it came in.

Q: Where did you end up applying and getting in?

A: Harvard, Yale, Princeton, University of Pennsylvania, Columbia University, UCLA, University of Michigan.

Congratulations Tracy!