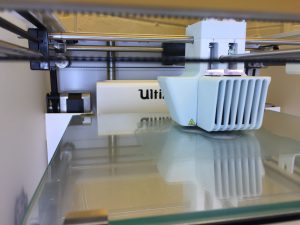

We are pleased to announce that Information Technology Services has just acquired a new 3D printer! And with this new printer, we hope to make 3D printing available to more folks here at Swarthmore.

With the arrival of the new Ultimaker 3 Fused Deposition Modeling (FDM) 3D printer, we’ve significantly expanded our capability for making objects here at the College. This new printer is significantly less expensive than our existing Dimension UPrint SE Plus, but offers even better resolution and similar print speeds. The Ultimaker 3 also offers some new features that really allow it to stand out in the field. First this system uses a dual print-head that allows it to print both model and support material like the UPrint, but these print-heads are modular and easily replaceable, so we can also switch to printing with two different model materials in a single print job. This will allow for two color printing as well as dual material printing for materials with different physical properties. The materials are easy and much quicker to change and load than our older 3D printer model.

This printer is also more flexible in that it can print with a variety of plastics and composite materials. In addition to the standard tough, stabile, impact resistant ABS (acrylonitrile butadiene styrene, has excellent mechanical properties – ideal for functional prototypes and complex end-use products, and can withstand temperatures of up to 85 ?C) used by the UPrint, the Ultimaker can also and will usually be set up to print, via a controllable variable temperature print-head, in the popular PLA (polylactic acid, a reliable, fantastic surface quality, made from organic, renewable sources, such as cornstarch fermentation and serves a wide range of applications for both novice and advanced users). This printer can also print in polycarbonate (for strong and tough parts that retain dimensional stability when subjected to temperatures as high as 110 ºC, flame retardant, strong interlayer bonding, and printing of translucent parts for lighting applications), flexible, durable, corrosion resistant Nylon (polyamide, a manufacturer’s favorite, with high strength-to-weight ratio, low-friction and flexibility, ideal for 3D printed tools, functional prototypes and end-use products), CPE (co-polyester, built for even tougher print jobs, chemical and temperature resistant, with dimensional stability, great for functional prototypes and mechanical parts).

On top of all of that, the support material used with the Ultimaker 3 is water soluble PVA (polyvinyl alcohol) which is a water soluble support material ideal for printing complex models in PLA or Nylon that require supports for large overhangs, deep internal cavities, and intricate geometries. This means that with this printer, we don’t have to remove support material through a high Ph wash station, rather we simply need to soak the printed objects in a tub of water!

The detailed specifications of this printer are impressive: the Ultimaker uses a 0.40 mm nozzle for a layer resolution of 200 to 20 microns (roughly ~8 thousandths of an inch to ~8 ten-thousandths of an inch, the best resolution of our Uprint is 10 thousandths of an inch). The heated glass build plate is temperature controlled to 20 ?C to 100 ?C depending on the material used in a project. It uses an active leveling build plate so we don’t have to constantly level it manually. Its dual extrusion print head allows for easily swappable print core replacement without tools, a new print-head is easy to slip in with your fingers. The build speed with the 0.40 mm nozzle is up to 16 mm³/s and the print head travel speed is 30 to 300 mm/s, depending on the job and settings. The material feeder is a dual geared feeder type for secure and consistent material to the print heads. The XYZ accuracy of this printer is selectable to 12.5(X), 12.5(Y), and 2.5(Z) microns! The nozzle has a controllable temperature range of 180 ?C to 280 ?C and will come up to temperature in under 2 minutes. The build plate will come up to temperature within 4 minutes.

One really nice feature is that this machine is also much quieter (50 dBA) than others of it’s type, and with an added door and containment, is even quieter, making it completely reasonable to operate in an office environment. While significantly smaller physically the Ultimaker also has a slightly larger available print volume than the UPrint, with this printer capable to print within a 7.8 x 8.5 x 7.9 inch space.

Another of the really nice new features of this printer is that it comes with a camera inside to allow you to monitor the printing of your object. It’s also possible to save that video stream to a file for later playback or documentation of your project being constructed. And you can monitor your print job wherever you have internet access.

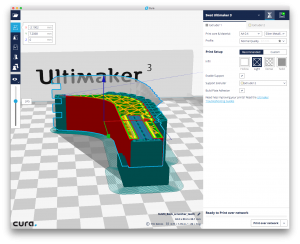

Ultimaker uses and supports the open source Cura software package, which has a really nice interface, that lets you see your print objects in layers, X-ray view as well as standard 3d view, as well as control the printer, monitor the print job both in details and through video. It gives you explicit control over the two print heads, so you can prep your designs for dual model materials, and for model and support building. As an open source project, this software can also be used for other 3D printers.

People are welcome to stop by Beardsley 105 or contact Doug Willen (x-7787 or willen@swarthmore.edu) for a look at the new printer, and to submit models to be printed. With the advent of this new printer our goal is to support the broader interest in 3D printing here on the campus. We’d like help folks to explore their ideas in 3 dimensions!