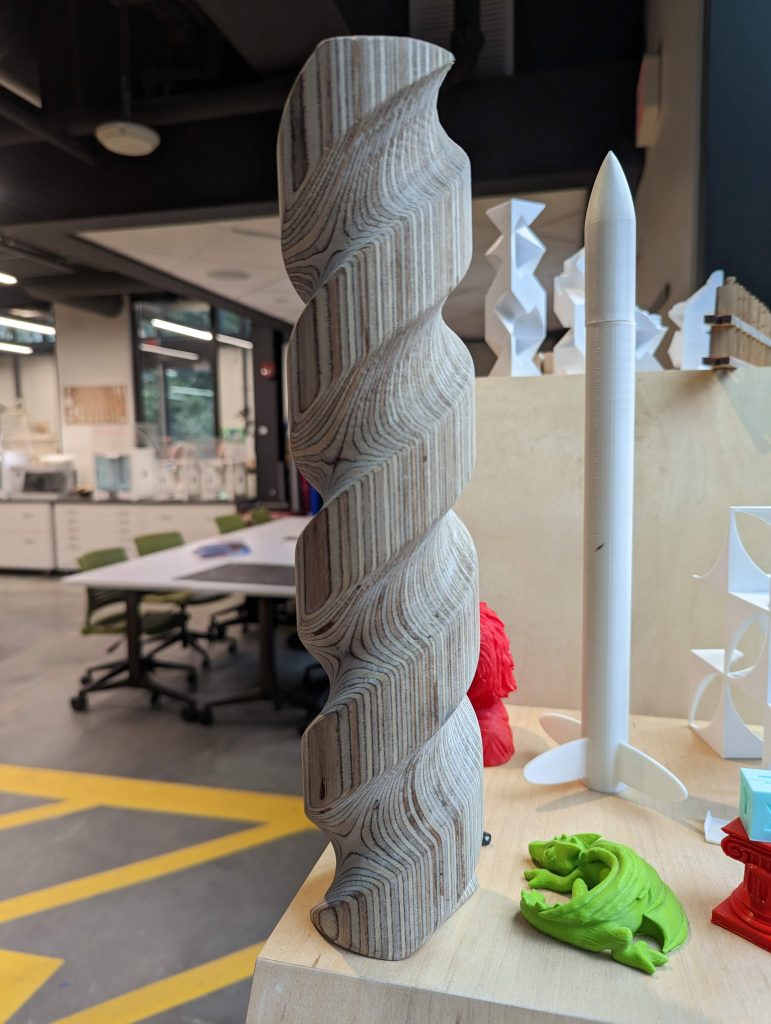

Here in the Makerspace we offer access to all sorts of tools for making: some known as analog, some called digital…

It’s tempting to see this as a clear division between old and new, hand-made and computerized, traditional and technological. But the distinction is blurrier, and in many ways, often much simpler.

You are probably familiar with the 3D printer as a modern benchmark for digital fabrication equipment. It certainly is computerized, automated, and the process takes relatively little hand work to execute. But how does your 3D printed part fit physically into your bigger construction? What kind of glue can bond the components you need? Does it need spray painting? This process can end up being quite improvised, opportunistic, and unexpected–and done largely by hand.

Likewise, many “traditional” tools have digital readouts or other mechanized controls, allowing you repeatability and automation beyond was is typically understood when one is “working by hand.” Is this digital fabrication?

The truth is, no tool is 100% digital or analog, and it’s your working process that’s the important part. Our makerspace tries to make this whole range of tools available, without too much preconception about what type of approach, attitude, or experience might get you into a certain kind of fabrication–digital or not.

Be on the lookout for a weekly calendar of Makerspace workshop events, in tools both analog and digital (and both simultaneously), starting after the Spring break!